High Temperature Heat Pump

Published at HTHP Annex58 in September 2023.

For more information:

https://heatpumpingtechnologies.org/annex58/task1/

Technology and Supplier Name

Pars Makina Ltd.

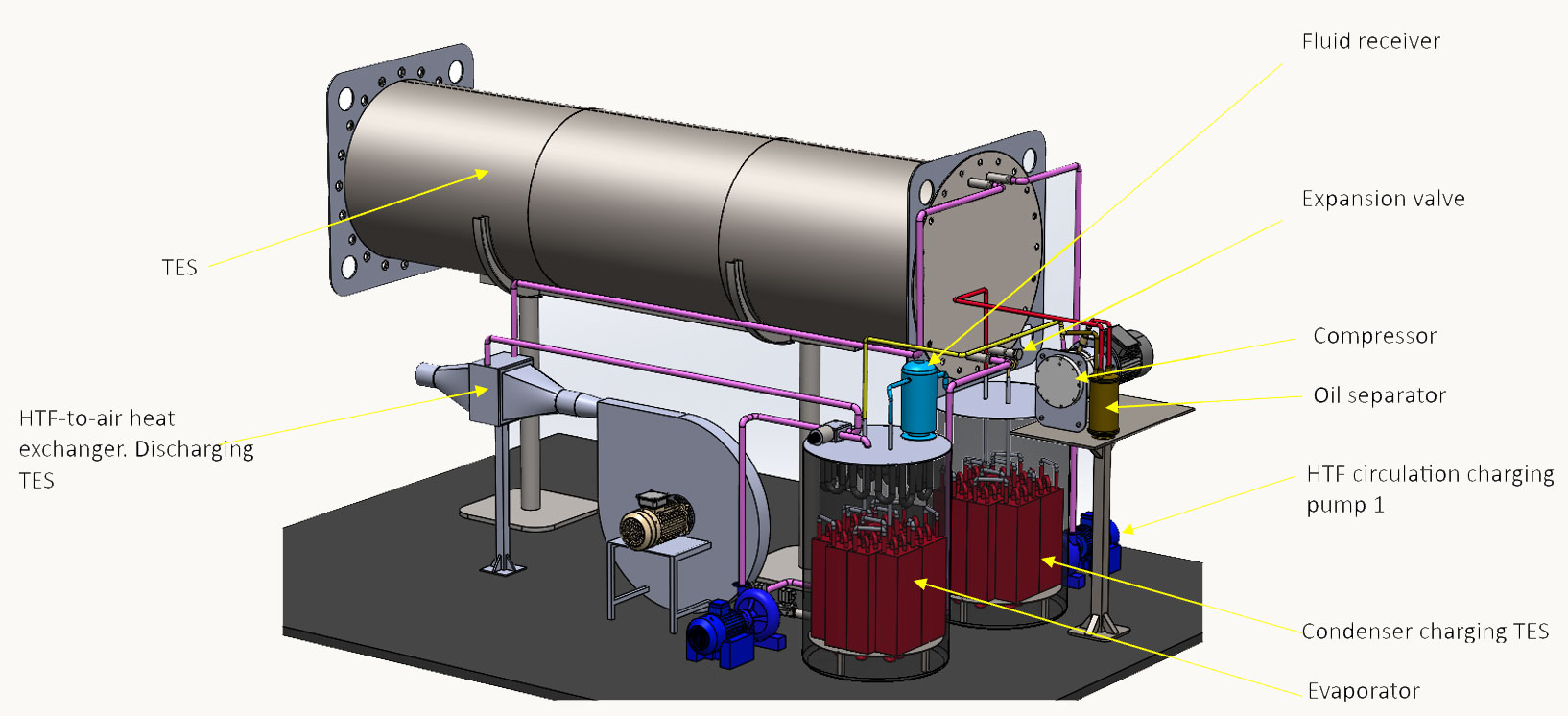

High Temperature Heat Pump (HTHP) + Thermal Energy Storage (TES) for low cost and efficient operations

Summary of The Technology / Product

InnoSolPower HTHP and TES

• Application: homes, schools and Industrial waste heat and processes

• Low-cost decarbonization solution for lower heat grades such as;

- heat from micro-size concentrated solar blocks (up-to 100°C),

- Underground/geothermal heat sources (up-to 100°C),

- excess electrical power heaters from roof-top PVs stored

as heat inside TES (PV charges TES in 5 hours)

• 100 kWh modules of µTES charge and discharge in 6 hours

- Up to 120°C: µTES-PCM contains PCM encapsulated tubes

- Up to 150°C: µTES-HTF contains heat transfer fluid (HTF)

- Up to 150°C Concrete filled µTES-C

• HTHP-15 (15 kW) charges a minimum of 4 µTES-PCM modules

- HTHP power units (15kW-30kW) are modular (parallel assembly)

- HTHP-15 footprint LxW: 1m x 1m, Weight: 250 kg

- µTES-PCM footprint LxW: 4m x 2m (modules of 25 kWh),

weight: 2.5 t.

- HTHP-15 charges the TES tank at a rate of 16.67 kWth

with a 1.75 kWe compressor input

• Modular capacity installations from 15 kW to 480 kW up to

8 compressors per unit. Highly flexible industrial operations,

• HCFO-1233zd(E) working fluid is harmless. Class A1, no toxicity and no flammability. ODP = 0, GWP < 5.

• Leak-proof pressure seals on the shaft side

• Compressor driven by a 2kWe open motor with controller

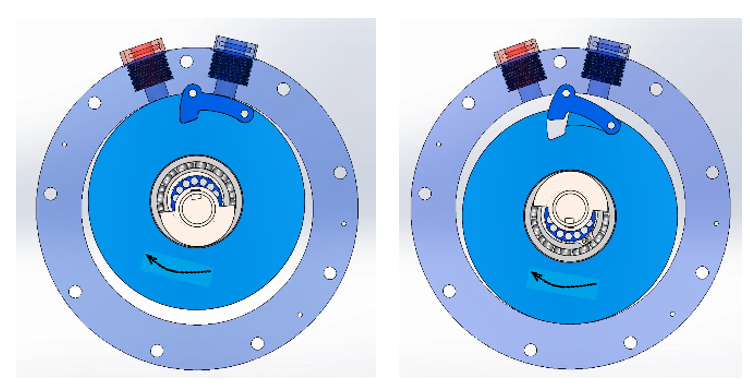

• Compressor architecture: patented double hinged arc vane rolling piston

• Lubrication: POE-SL-68

• HTHP pilot plant at TRL6 as the technology is demonstrated in industrially relevant environment.

• Heat Transfer Fluid (HTF) on sink and source side is mineral based Renotherm 320 with high thermal stability up to 320°C.

Summary of Technology

Product is a hybrid electrical/thermal energy storage composed by a novel high temperature heat pump and the thermal energy storage tank. Integration of

heat pump and storage is optimized as operating temperatures and pressure

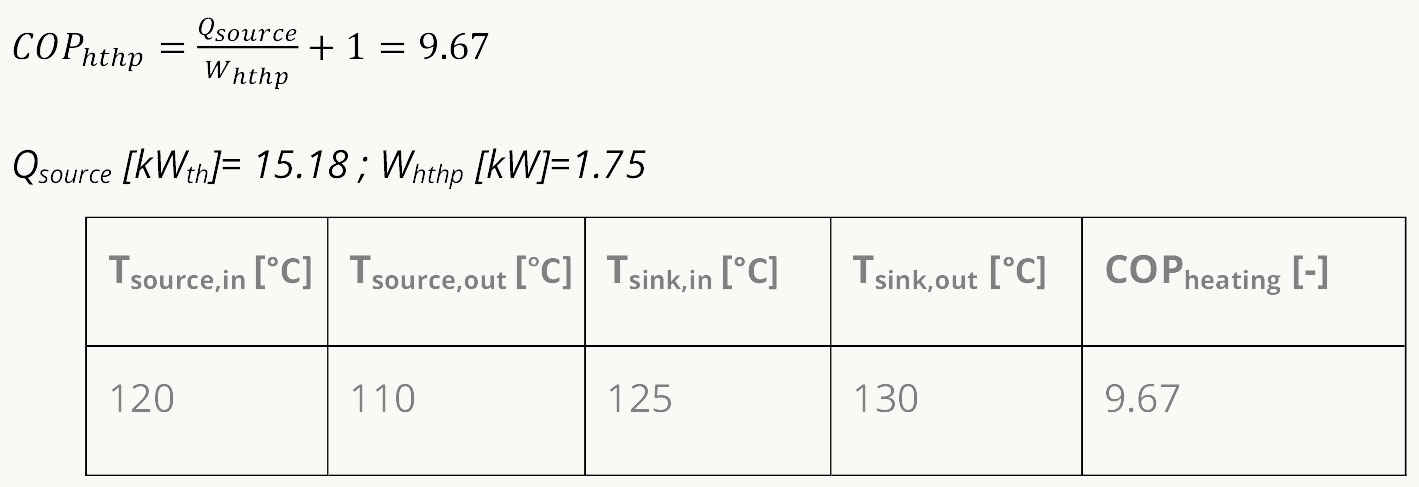

ratios are specifically chosen for highest operational efficiency. Calculated COP is around 9.67.

• Standard and modular units HTHF-15 and HTHF-30 (15kW-30kW)

• Offered with three different non-pressurized TES configurations:

- µTES-PCM, µTES-HTF and µTES-C (modular approach)

• Heat exchangers (HXs): evaporator and condenser have each 13.05 m2

heat transfer surfaces. 29m finned copper piping. Hot oil circulation pumps move 100 Lt HTF within HXs

• Flexible operation: heat pumps operate most efficiently at 100%

compressor capacity and with a TES. Thus, it is easy to follow

“plant heat-load demand” mode of operation.

Performance Data

Project Example

HTHP-15 is demonstrated at full scale in the context of InnoSolPower (CSP ERA-NET grant agreement No. 838311).

Performance tests are scheduled to end December 2023.

• Tested operating temperature are between 100°C-130°C and pressures are between 12.4 bar-19.6 bar.

Results are presented to InnoSolPower Advisory Group Members.

• Key Performance Indicators (KPIs) ar: high density,

high latent heat of fusion, high specific heat, melting point near the

required operational temperature (120°C), high thermal conductivity,

low vapor pressure, high thermal stability, high chemical stability, low cost,

high market availability and low tank size.

HTHP technology extensions are: trans-critical and supercritical CO2

Facts About Technology

Heat supply capacity: Modules of 15kW-30kW-60kW,

combined units up to 480 kW

Temperature range: maximum supply temperatures 150°C. HTHP can supply maximum supply heat up to 150°C, such as maximum temperature lift of 20°C. Maximum temperature glides in source is 20°C and at the sink, 25°C

Working fluid: R1233zd(E)

Compressor technology: patented rotary doubled hinged arc vane

Specific investment cost for installed system without integration: Combined HTHP-15 + µTES-PCM cost: 1500 €/kW

TRL level: TRL6

Expected lifetime: 25 years with regular yearly maintenance

Size: HTHP alone weight 250kg and footprint 1 m²

HTHP + TES weight 2500kg and footprint 8 m²

Pars Makina From All Perspectives

Eco-Friendly

In all our projects that we carry out, we strive to use renewable energy sources and equally, we prefer to use recyclable materials.

Work Ethics

We add our motivation and ethical values to our continuous development efforts and we realize our projects through an evolving design that take into account feedbacks from numerous simulation and tests.

Safety

We always place safety the first place. We prioritize worker healthin all type of field works, factory production, assembly and tests carried out in our workshop.

Social Responsibility

Through the development of high and ınnovatıve technologies, we fulfil our duty regarding the development of our country and entire world wellness.

Advanced Technology

We always provide world-class engineering and production services with our R & D and production team that follows the technological state-of-the-art in our fields of expertise.

Customer Focused

We ensure customer satisfaction by providing efficient and reliable products that emanate from our responsible and positive-thinking attitude.

Look at Us More Closely

Pars Makina develops novel technological products that results from long term fundamental R&D studies. Our intellectual property contains many recent national and international patents that increase our worldwide competitiveness. For sustained growth of our capabilities and increased market share, we continue to produce state-of-the-art solutions involving high technologies. We also strive to work closely with national and international academic institutions and leading large companies in Turkey and Europe.

Pars Makina

We provide reliable, economical, high-power and efficient innovative solutions in the fields of Transport, Defence, Aerospace, Aerospace Engineering and Clean Energy.