High Temperature Heat Pump Compressor

Pars Makina Ltd

Published at HTHP Annex68 in September 2025.

For more information:

https://heatpumpingtechnologies.org/project68/task1/

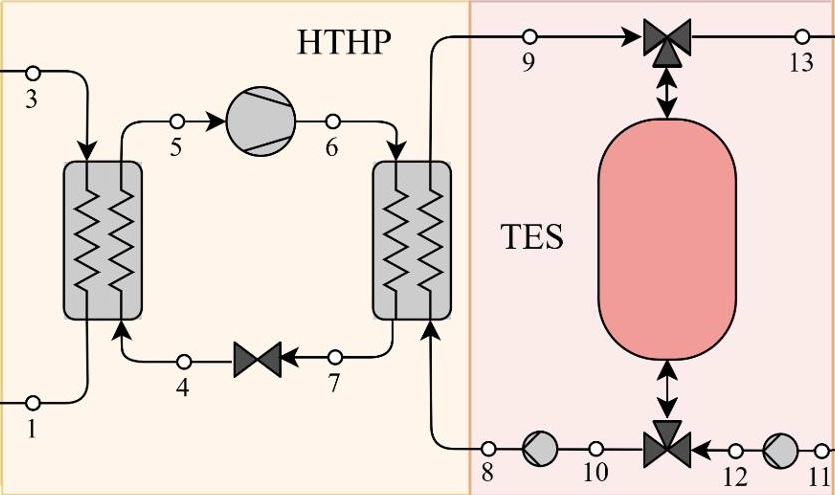

Figure 1: HTHP Equipped with High Precision Double Hinged Arc Vane Compressor

Summary of technology

- At the heart of the HTHP, there is a novel double hinged arc vane compressor (Fig.1) driven by a vertically placed electrical motor. Main features are listed below.

- Closed loop HTHP is equipped with oil-to-refrigerant evaporator and condenser (Fig.2);

- Compressor eccentric shaft (5mm) allows for low torque arm and as such, ensures the lowest input shaft power in its class,

- Double hinges of the arc vane compressor fully eliminate sliding frictions that are inherently present in swing-vane type and other spring-vane type commercial rolling piston compressors;

- HTHP part load capabilities range from 20% up to 100% thanks to electrical inverter motor;

- The HTHP cycle is charging a high temperature thermal energy storage tank for commercial applications;

- We provide low-cost decarbonization solution for revalorization of low-grade heat from:

- Air heat source (-10°C to 100°C)

- Geothermal heat sources (10°C to 130°C),

- Each HTHP has a maximum installed thermal power of 1 MW. Each rack is combining standard compressors in series, each contributing to a rated heat pump power of 25kWth, 75kWth, and 125kWth;

- Lubrication oil is PAG68 and oil quantity is 0.75 Lt;

- No oil pump is needed;

- Development status has now reached TRL6 at the factory test bench;

- The Heat Transfer Fluid (HTF) on the sink and source sides is mineral-based Renotherm 320. Refrigerant-to-HTF heat transfer in the evaporator and condenser are achieved through 13.05 m2 of heat transfer surfaces and 29 m of finned copper piping. Hot oil circulation pumps move 100 liters of HTF within the condenser to the Thermal Energy Storage (TES).

Figure 2: Operational HTHP+TES prototype configuration

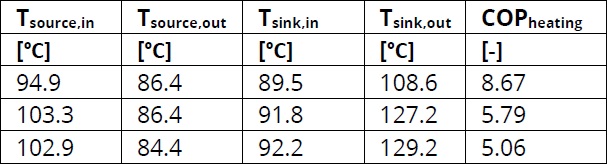

Table 1: Measured performance on factory test bench.

All information were provided by the supplier without

third-party validation. The information was provided as

an indicative basis and may be different in final

installations depending on application specific

parameters.

Project example

InnoSolPower project has been supported under the umbrella of CSP-ERA.NET (Cofound ERA-NET Action, G.A. N° 838311). The project is now completed. This technology is highly flexible for different industrial operations and heat needs. Pars Makina Ltd (PML) has designed, developed, manufactured and tested a double hinged arc vane compressor for a high temperature heat pump (HTHP) with a discharge temperature well over 130°C. Closed volume compression allows the pumping of a nominal mass flow rate around 0.14 kg/s of R1233zd(E) with very high volumetric efficiencies.

Main thermodynamic performance indicators are:

Volumetric efficiency: the smaller the internal leakage, the more the volumetric efficiency increases. Volumetric efficiency is over 90%,

Compressor pressure ratio: 1.58 for R1233zd(E),

Compressor volume ratio: 1.72 for R1233zd(E),

Compressor discharge pressure: 19.55Bar for R1233zd(E),

Volumetric flow rate: 2.9Lt/s for R1233zd(E),

Reliability & Operating Life Expectancy: roll-cake topology of hinged-vane rolling piston compressor and oil film prevent direct contact with the internal surface of the cylindrical housing. The compressor can operate for over 100,000 hours (2 to 3 times that of rotary screw compressors) without wear.

Main economic performance indicator: to provide low cost and very efficient high temperature industrial heat pump compressors. Our potential customers are heat pump manufacturers, heat pump installers and repair shops,

HTHP technology extensions: supercritical CO2 (R744) compressors and expanders.

Installation and test start date: January 2024

Contact information

Dr. Sinan Akmandor, Pars Makina Ltd

Compressor-Pump

Published at HTHP Annex58 in September 2023.

For more information:

https://heatpumpingtechnologies.org/annex58/task1/

Novel CO2 Compressor Under Development

Left: Pars Makina double hinged arc vane: compact, no leakage, no friction, suction: blue, discharge: red

Middle: Spring loaded vane: leakage and friction,

Right: Swing vane: no leakage but vane-swing vane friction

• Semi-hermetic architecture.

• Electrical motor is operating at expander outlet temperature (35C) and pressure (40.7bar),

Direct coupling allows ease of compressor-expander alignment,

Pars Makina From All Perspectives

Eco-Friendly

In all our projects that we carry out, we strive to use renewable energy sources and equally, we prefer to use recyclable materials.

Work Ethics

We add our motivation and ethical values to our continuous development efforts and we realize our projects through an evolving design that take into account feedbacks from numerous simulation and tests.

Safety

We always place safety the first place. We prioritize worker healthin all type of field works, factory production, assembly and tests carried out in our workshop.

Social Responsibility

Through the development of high and ınnovatıve technologies, we fulfil our duty regarding the development of our country and entire world wellness.

Advanced Technology

We always provide world-class engineering and production services with our R & D and production team that follows the technological state-of-the-art in our fields of expertise.

Customer Focused

We ensure customer satisfaction by providing efficient and reliable products that emanate from our responsible and positive-thinking attitude.

Look at Us More Closely

Pars Makina develops novel technological products that results from long term fundamental R&D studies. Our intellectual property contains many recent national and international patents that increase our worldwide competitiveness. For sustained growth of our capabilities and increased market share, we continue to produce state-of-the-art solutions involving high technologies. We also strive to work closely with national and international academic institutions and leading large companies in Turkey and Europe.

Pars Makina

We provide reliable, economical, high-power and efficient innovative solutions in the fields of Transport, Defence, Aerospace, Aerospace Engineering and Clean Energy.