FIDELITY POINTWISE

Preprocess software that produces robust, high quality mesh for CFD calculations

Mesh quality is the key to converged and accurate CFD solutions. With Cadence Fidelity Pointwise, you get all the tools you need to achieve the desired results – high levels of automation plus detailed levels of control. Pointwise guides you through the process of dealing with less-than- perfect geometry models to formatting the most robust grid for your flow solvers. Once your mesh is complete, you can export it along with flow solver boundary conditions to many popular open-source, commercial, and standard CFD formats. All of this, from import through meshing and export, can be automated using our Glyph scripting language. Our commitment to your success begins with your Pointwise evaluation. Whether you encounter a technical issue or just need advice to get the most from Pointwise, our industry-tested engineers are ready to help. This attention does not stop when you license Pointwise. We generate more than grids – ultimately, we build and nurture long-term relationships. It’s no wonder we maintain a greater than 95% retention rate with our clients.

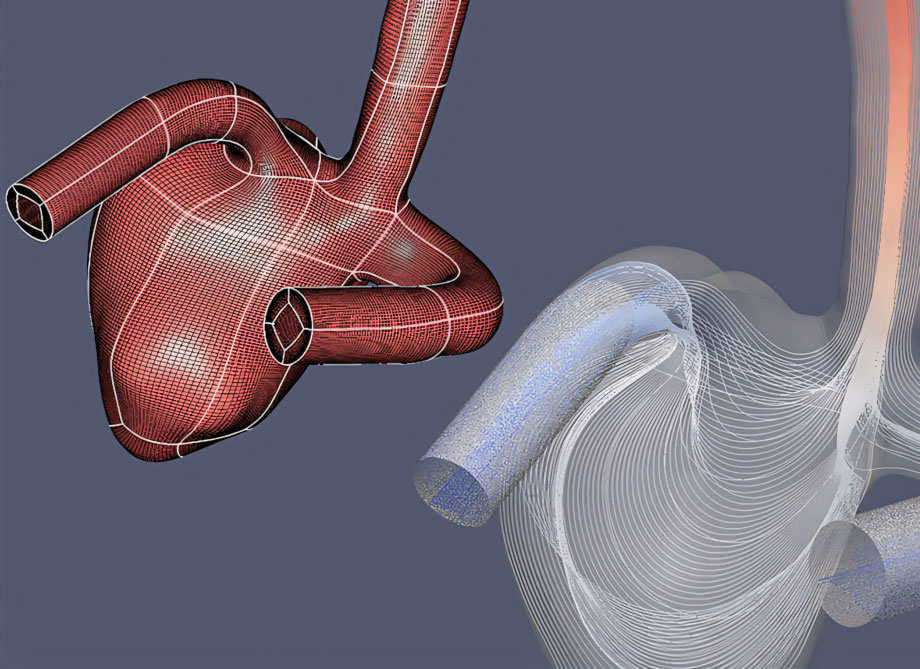

Solid Modeling, Fault-Tolerant Meshing, and Mesh-Geometry Independence

Fidelity Pointwise’s suite of solid modeling operations is designed to form imported geometries into watertight solids where gaps are closed implicitly so that meshing can proceed without a hitch. Alternatively, a technique called merging automatically identifies adjacent surface meshes, joins them across geometry model gaps, and uses the mesh solver to remove geometry artifacts such as topology and sliver surfaces from the mesh. Furthermore, Fidelity Pointwise’s built-in geometry modeler may be used to supplement what is imported from a CAD system or even create new models from scratch.

Meshing Features

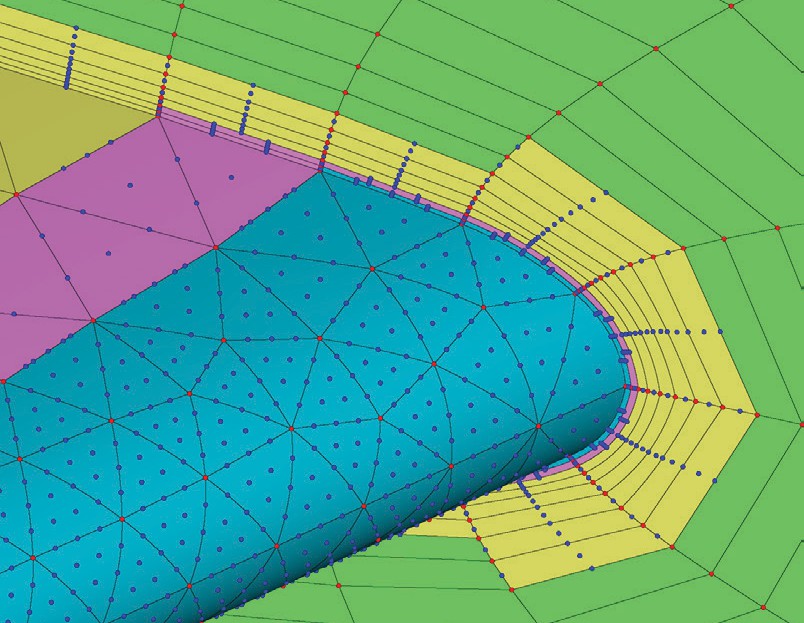

Hybrid viscous meshing

Fidelity Pointwise’s suite of solid modeling operations is designed to form imported geometries into watertight solids where gaps are closed implicitly so that meshing can proceed without a hitch. Alternatively, a technique called merging automatically identifies adjacent surface meshes, joins them across geometry model gaps, and uses the mesh solver to remove geometry artifacts such as topology and sliver surfaces from the mesh. Furthermore, Fidelity Pointwise’s built-in geometry modeler may be used to supplement what is imported from a CAD system or even create new models from scratch.

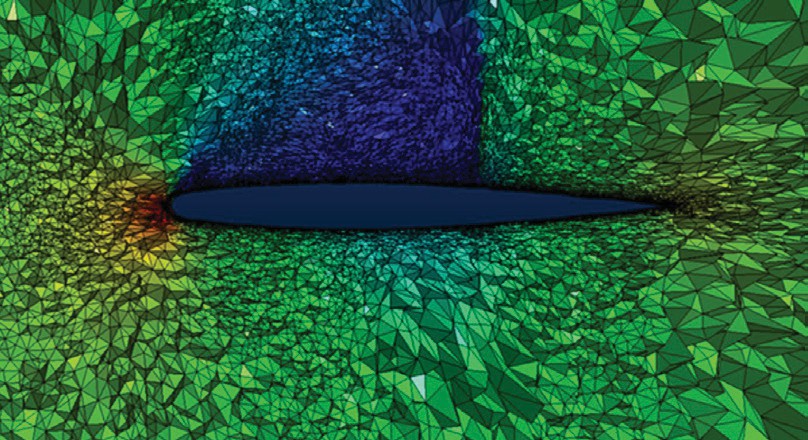

Solver-agnostic mesh adaptation

Take the guesswork out of a priori mesh refinement by performing user-independent adaptation. Fidelity Pointwise supports solver-driven volume and surface-constrained mesh refinement to improve simulation accuracy.

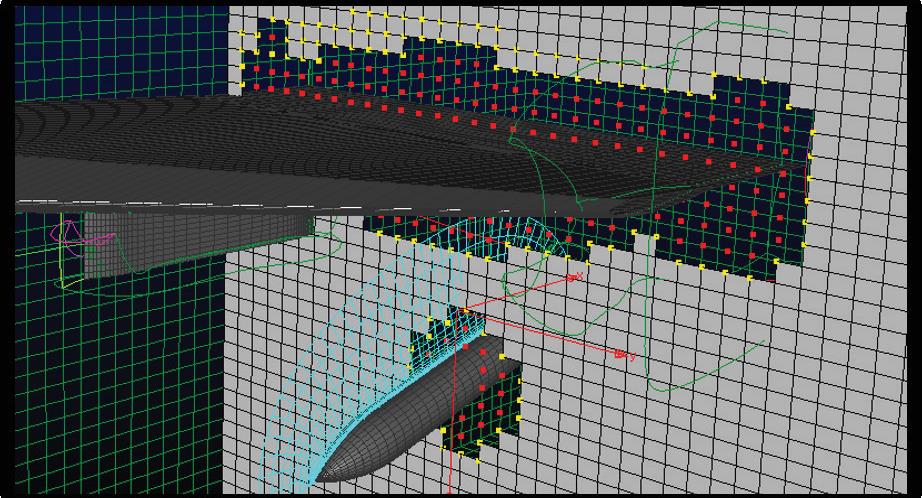

Overset meshing

With direct interfaces to the industry’s most robust overset grid assemblers, Fidelity Pointwise can run the entire assembly process, visualize overset meshing results, and perform remediation through mesh adaptation.

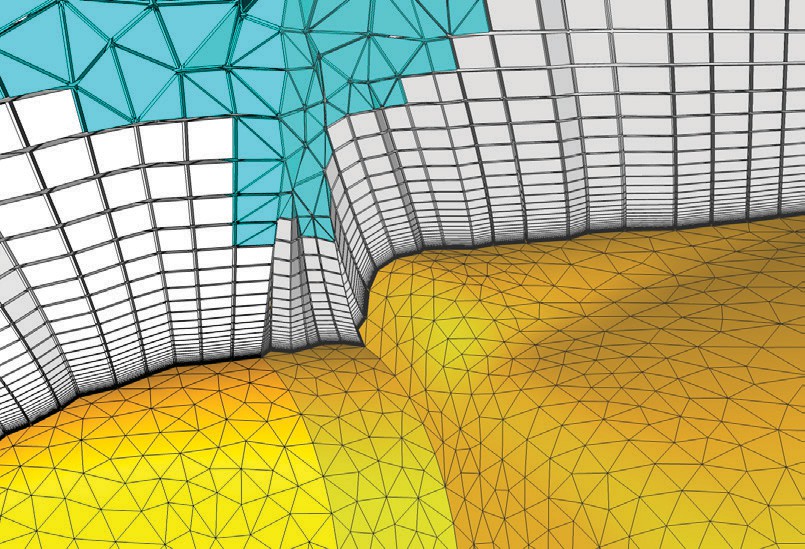

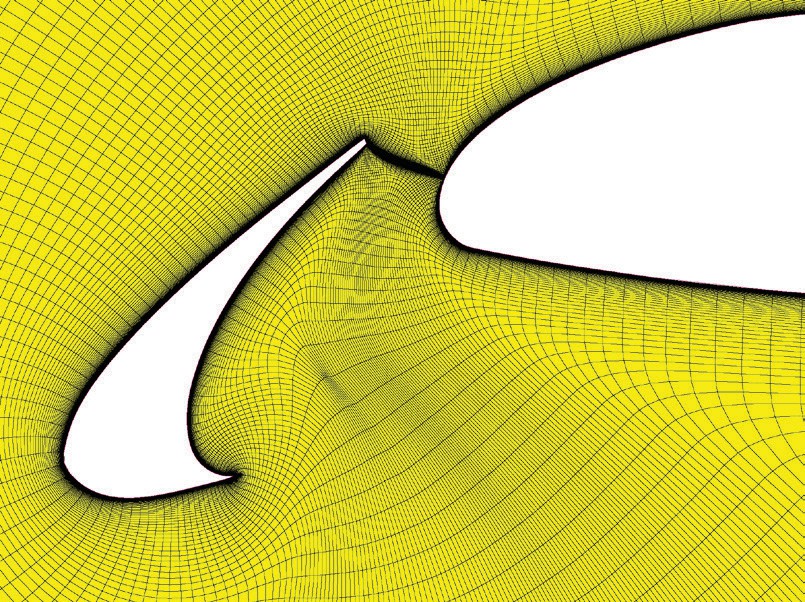

Structured meshing

Fidelity Pointwise’s best-in-class quad and hex meshing techniques have been honed since 1984. Elliptic and hyper- bolic PDE-based smoothing, algebraic extrusions, and other technologies enable the creation of high-quality structured meshes that industrial users have relied on for decades.

High-order meshing

To generate the high-order meshes that high-order solvers require, Fidelity Pointwise features an optimization-based high-order meshing technology. This allows using fewer elements to resolve curved geometry while improving spatial and temporal accuracy.

Automation and Compatibility Features

CAE solver interfaces

Fidelity Pointwise supports neutral, native, and de facto standard interfaces to CAE solvers (including the specification of solver boundary conditions) and a variety of other formats to ensure that Pointwise fits into your analysis process.

Flashpoint

Flashpoint combines the level of control and expertise for which Pointwise is known with deeper automation. By specifying goals for the mesh, Pointwise will automatically- generate a geometry-resolving, hybrid, unstructured mesh with anisotropy. This process ensures consistency and reliability throughout the meshing process while also providing a framework for encapsulating your organization’s best practices.

Glyph Scripting

Fidelity Pointwise’s scripting language, Glyph, provides customization capabilities for both the experienced analyst and design engineer. Analysts will find that Glyph’s commands cover the entire range of functionality available in Fidelity Pointwise’s GUI, allowing special techniques to be captured and made part of your organization’s intellectual property. Design engineers will appreciate the fact that Glyph can be used to create customized meshing applications for specific configurations, allowing them to automatically generate a mesh and apply CFD.

Pars Makina From All Perspectives

Eco-Friendly

In all our projects that we carry out, we strive to use renewable energy sources and equally, we prefer to use recyclable materials.

Work Ethics

We add our motivation and ethical values to our continuous development efforts and we realize our projects through an evolving design that take into account feedbacks from numerous simulation and tests.

Safety

We always place safety the first place. We prioritize worker healthin all type of field works, factory production, assembly and tests carried out in our workshop.

Social Responsibility

Through the development of high and ınnovatıve technologies, we fulfil our duty regarding the development of our country and entire world wellness.

Advanced Technology

We always provide world-class engineering and production services with our R & D and production team that follows the technological state-of-the-art in our fields of expertise.

Customer Focused

We ensure customer satisfaction by providing efficient and reliable products that emanate from our responsible and positive-thinking attitude.

Look at Us More Closely

Pars Makina develops novel technological products that results from long term fundamental R&D studies. Our intellectual property contains many recent national and international patents that increase our worldwide competitiveness. For sustained growth of our capabilities and increased market share, we continue to produce state-of-the-art solutions involving high technologies. We also strive to work closely with national and international academic institutions and leading large companies in Turkey and Europe.

Pars Makina

We provide reliable, economical, high-power and efficient innovative solutions in the fields of Transport, Defence, Aerospace, Aerospace Engineering and Clean Energy.